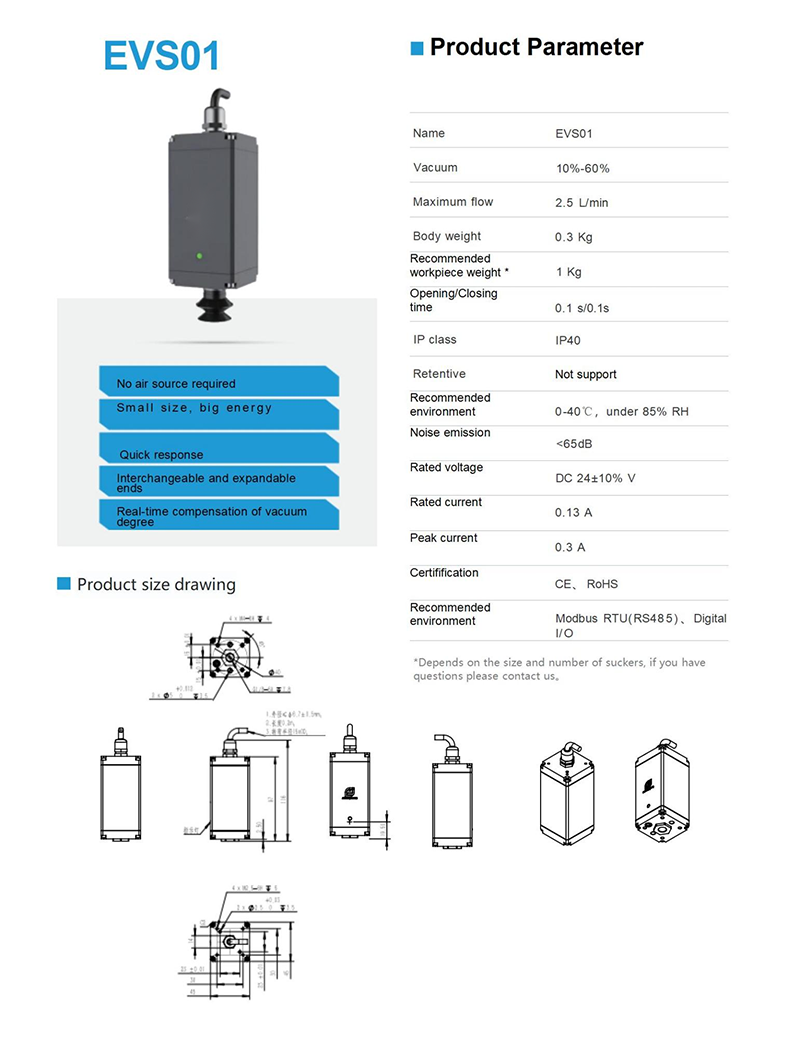

Ngokombono wesakhiwo esisebenzayo, ukuphunyezwa kwejeneretha yokucoca ikakhulu ivalve yokulawula i-electromagnetic ukulawula i-vacuum generator ukuqonda ukuveliswa koxinzelelo olubi kunye nokuyeka, ukuze kuphunyezwe umsebenzi wokutsala kunye nokukhulula i-workpiece.

Ngenxa yoko, inkqubo ngokubanzi ibandakanya la macandelo alandelayo: 1. Umthombo womoya oxinanisiweyo;2. Isihluzo;3. Tshintsha ivalve ye-solenoid;4. Isixhobo sokuvula;5. Ukuphelisa ikomityi yokufunxa, ingxowa yomoya, njl njl. (Isakhiwo esiqhelekileyo siboniswe kumzobo ongezantsi).

Ukongeza, phantsi kweemfuno ze-automation ye-industrial, ukuze kuqatshelwe ukujongwa kwenkqubo ye-adsorption ye-vacuum, abanye abavelisi ngokubanzi bongeza amacandelo olawulo lwe-pneumatic njengeemitha zokuhamba, ukutshintshwa koxinzelelo, kunye nokutshintsha okusondeleyo kwinkqubo kwiminyaka yamuva.

Nangona kunjalo, ekubeni uninzi lwamacandelo lulungiswa ngumdibanisi ngokweemfuno zabathengi kunye neemeko zokusebenza kwindawo, ubunzima benkqubo yonke buhlala buphezulu.

Ngelo xesha, abavelisi bamacandelo amaninzi bakhokelela kufakelo olunzima kunye nomsebenzi wokuthuma kwisayithi, kwaye abanye babo basebenzise amandla aphezulu kunye nokuxhomekeka kwe-100% kwimithombo yegesi.Udibaniso oluyinxenye lusenokungenzeki

Gwema ukungcoliseka kwengxolo, oku kuthetha iingxaki ezingamkelekanga kwiindawo ezichanekileyo kunye nezicocekile eziphezulu ezifana neebhetri ze-lithium kunye ne-semiconductors.

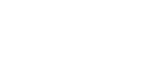

Lilonke, i-EVS sisizukulwana esitsha se-actuum yombane ekrelekrele engadingi mthombo womoya owongezelelweyo ocinezelekileyo, ngokungathandabuzekiyo otsala amehlo.

Inzuzo enkulu yenkqubo yokugcina umoya kukulula kwayo ukufakela.Kuba oku ngokungathandabuzekiyo kunokunciphisa amacandelo amaninzi ancedisayo, kubandakanywa iicompressors zomoya, iitanki zokugcina umoya, izixhobo zokucoca umoya, kunye nemibhobho ephumayo, njl.

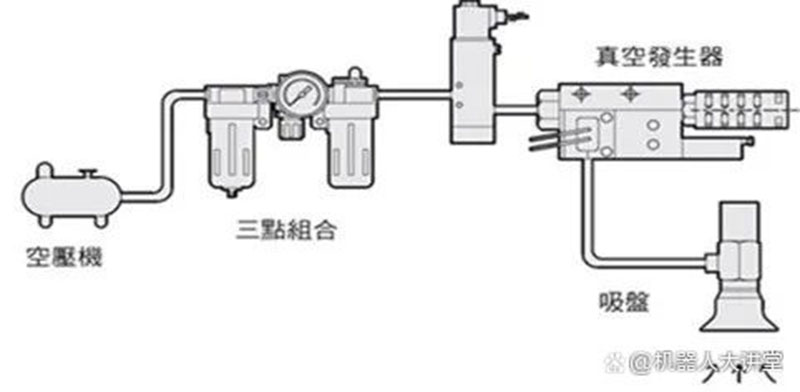

Kuxelwe ukuba okwangoku, izigcawu ezininzi ezibandakanya iiplatifti zerobhothi ezihambayo, indibano ye-elektroniki ye-3C, ukwenziwa kwebhetri ye-lithium, ukwenziwa kwe-semiconductor, i-express logistics, njl.

I-EVS08 ibhetri yokufunxa isikwere

Iinkcukacha ezininzi kunye neenzuzo

Iholo yokufundisa irobhothi ifunde ukuba le mveliso, ekhangeleka incinci kakhulu kwaye inobunzima obuyi-2.5kg kuphela, inokufikelela kwinqanaba eliphezulu le-10kg.Ngenxa yoyilo lwe-24V ephantsi kwe-voltage, ukusetyenziswa kwamandla yi-20% yenkqubo ye-pneumatic yendabuko, kwaye i-adsorption force ekupheleni inokumiselwa kwaye ihlengahlengiswe, kwaye i-adsorption force inokufikelela kwi-102-510N.

Ngokumalunga noyilo lwesakhiwo, i-EVS ithatha i-compact kunye ne-lightweight structural design, eyenza i-EVS i-30% encinci kune-aerodynamics yendabuko yobunzima obufanayo bomthwalo.

Kwangaxeshanye, inokudityaniswa ngokuthe ngqo kwikhonkco ekupheleni kwengalo yerobhothi, enciphisa amacandelo ancedisayo angafunekiyo, iyenze ibe bhetyebhetye ngakumbi ukuyisebenzisa, inokuhanjiswa ngokukhawuleza, kwaye ikwazi ukufunxa ngokulula izinto ezininzi ezikhulu, ezilungele ngakumbi. ukupakisha, ukuphatha kunye neminye imisebenzi yendawo.

Ukuze kuphuculwe ukusebenziseka lula, i-actuator yombane yombane nayo ine-interface edibeneyo, engasetyenziselwa ukulawula nokubeka iliso kuyo yonke inkqubo yezinto ze-adsorbing.

Kuxelwa ukuba oku kwenzelwa lula abathengi ukulawula idigri yevacuum ye-vacuum actuator ngokusebenzisa imiyalelo, kwaye badibanise ngekhonkco le-IO lokubeka iliso kunye nokugcinwa kwangaphambili kwenkqubo ye-adsorption.Ukujongwa kwesimo kuya kunciphisa iimpazamo kunye nexesha lokunciphisa kunye nokuqinisekisa ukufumaneka kwenkqubo.

Kwesi siseko, iingenelo kunye neempawu ze-EVS nazo zibonakaliswa kula manqaku alandelayo:

1. Ubume be-Compact kunye nobunzima obulula: I-EVS yi-30% encinci kunobukhulu be-pneumatic yendabuko xa ithatha ubunzima obufanayo bomthwalo.Inokudibaniswa kunye nekhonkco ekupheleni kwengalo yomatshini ukuqonda ukufunxa komthwalo, ngokukodwa ngokufanelekileyo ukupakisha, ukuphatha kunye neminye imisebenzi yescene;

2. Ubume betheminali eninzi: Iindidi ngeendidi zeekomityi zokufunxa, ii-airbags kunye namanye amacandelo anokwakheka ukuqonda ukubamba izinto ezahlukeneyo, kubandakanywa isikwere, i-spherical kunye nemilo eyodwa;

3. Iziteshi ezimbini ziyakwazi ukulawulwa ngokuzimeleyo: lawula ngokulula amacala asekhohlo nasekunene e-vacuum actuator, kunye namacala amabini azimeleyo omnye komnye, ukuphucula ngakumbi ukusebenza kakuhle komgca wokuvelisa.Iqaphela ukufunxa kunye nokubekwa kwangaxeshanye, okuququzelela kakhulu ukuphathwa kunye nokuhlelwa kwezinto, ukugcina indawo kunye nexesha;

4. Ukufunxa okunokulungiswa: iqondo le-vacuum linokuhlengahlengiswa ngokweempawu zemveliso efunxiweyo, kwaye imbuyekezo yevacuum yexesha langempela inokufezekiswa;

5. Ingxelo yesimo: Ine-vacuum feedback sensor, enokubona imeko ye-adsorption yezinto ngexesha langempela, kwaye inike ingxelo kunye ne-alamu;

6. Ukhuseleko lokuvala amandla: Emva kokucinywa kombane, inokuqonda i-adsorption power-off self-locking ukukhusela izinto ze-adsorbed;

7. Ukulungelelaniswa okuqinileyo: inkxaso ye-24V I / O kunye ne-MODBUS RTU (RS485) iprotocol yonxibelelwano;

8. Kulula ukuyifaka kunye nokulungiswa: iprotocol yonxibelelwano ilula kwaye ifundeka, enciphisa kakhulu ubunzima bokulungisa.Ukongeza, isoftware yokulungisa ikhompyuter yomkhosi inokudityaniswa njengesipho, esinokusetwa kwaye sihlelwe ukuseta iiparamitha zokusebenza ngaphandle kweintanethi.

Isiphelo kunye nekamva

Ngaphantsi kwendlela yokwenza izinto ezizenzekelayo kunye nobukrelekrele, ii-actuator zombane ziye zanda ukuba yinxalenye ephambili yokuqinisekisa ukusebenza okuqhelekileyo kweerobhothi kunye neenkqubo ezizenzekelayo, zenza ukuba ukusetyenziswa kweenkqubo zombane zombane kube lula kwaye kulula ukuzisebenzisa, kwaye zinokuhlangabezana neemeko ezahlukeneyo ezifana iirobhothi ezidibeneyo eziphathwayo..

I-interface edibeneyo kunye nokucwangciswa kwe-terminal ecebileyo kunye nokunye ukulungelelaniswa kunokuphucula ngakumbi ukuthembeka kwamacandelo abalulekileyo e-robot, ukunciphisa ukumiswa kwemveliso kunye neengxaki zokuthunyelwa kude kubasebenzisi bokugqibela, kunye nokunciphisa ngakumbi ukugcinwa kunye neendleko zokuthengisa emva kokuthengisa.

Ixesha lokuposa: Apr-19-2023