Kwiirobhothi zamashishini, izinto zokuphatha sesinye sezicelo ezibaluleke ngakumbi kwimisebenzi yazo yokubamba.Njengoluhlobo lwezixhobo zokusebenza ezinokuguquguquka okunamandla, ukugqitywa ngempumelelo komsebenzi wokusebenza kwerobhothi yoshishino ngokuthe ngqo kuxhomekeke kwindlela yokudibanisa.Ke ngoko, indlela yokubambelela ekupheleni kwerobhothi kufuneka iyilwe ngokweyona misebenzi isebenzayo kunye neemfuno zendawo yokusebenza.Oku kukhokelela ekuhlukeni kweefom zesakhiwo se-clamping mechanism.

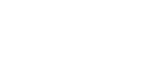

Umzobo 1 Ubudlelwane phakathi kwezinto, iimpawu kunye neeparamitha zesiphumo sesiphelo Uninzi lweendlela zokubambelela koomatshini luhlobo lweminwe emibini yozipho, olunokwahlulwa lube: uhlobo olujikelezayo kunye nodidi loguqulo ngokwendlela yentshukumo yeminwe;iindlela ezahlukeneyo zokubambelela zinokwahlulwa zibe yinkxaso yangaphakathi Ngokweempawu zesakhiwo, inokwahlulwa ibe yintlobo ye-pneumatic, uhlobo lombane, uhlobo lwe-hydraulic kunye ne-clamping yabo edibeneyo.

I-pneumatic end clamping mechanism

Umthombo womoya wothumelo lwe-pneumatic ulunge ngakumbi ukufunyanwa, isantya sentshukumo siyakhawuleza, indawo yokusebenza ayingcoliseki, kwaye ulwelo lungcono kunenkqubo yehydraulic, ilahleko yoxinzelelo incinci, kwaye ifanelekile ixesha elide- ulawulo lomgama.Ezi zilandelayo zizinto ezininzi ze-pneumatic manipulators:

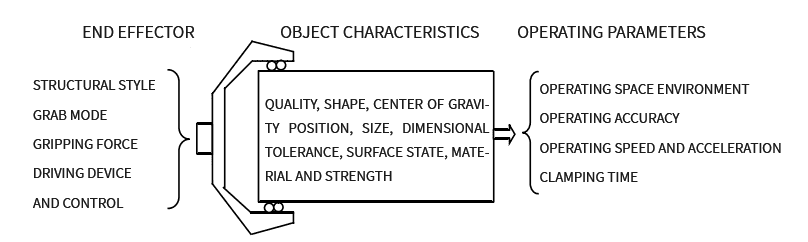

1. I-Rotary link lever-type clamping mechanism Iminwe yesi sixhobo (efana neminwe engu-V, iminwe egobileyo) igxininiswe kwindlela yokudibanisa ngeebholithi, ekulula ukuyibuyisela, ngoko inokwandisa kakhulu ukusetyenziswa kwe indlela yokubamba.

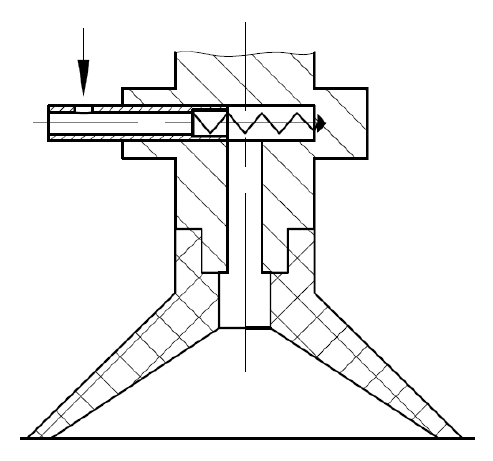

Umzobo 2 Ikhonkco elijikelezayo leleva yohlobo lwesakhiwo sendlela yokubambelela 2. Intonga ethe tye Uhlobo lwentonga ephindwe kabini yokuguqulela indlela yokudibanisa Isiphelo somnwe wale ndlela yokudibanisa ikholisa ukufakwa kwintonga ethe tye enesitulo sokuxhoma somnwe ekupheleni.Xa kusetyenziswa imingxunya emibini yeentonga zesilinda esisebenza kabini, ipiston iya kuhamba ngokuthe ngcembe iye embindini de i-workpiece ibambene.

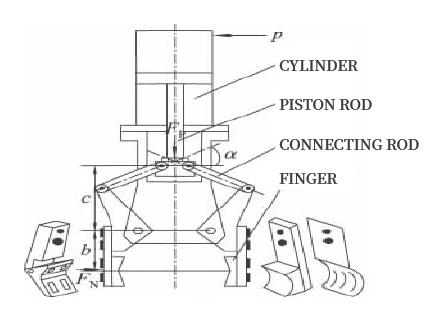

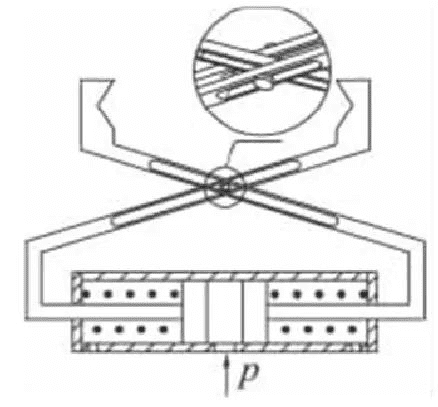

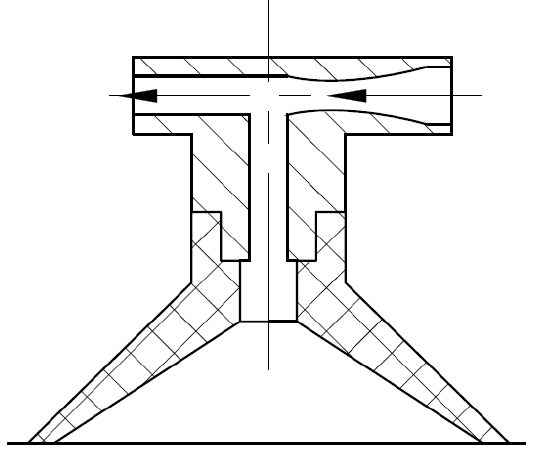

Umzobo 3 Umzobo wesakhiwo sendlela yokudibanisa intonga ephindwe kabini yoguqulelo 3. Intonga edibanisayo yohlobo lwe-double-cylinder yokuguqulela indlela yokudibanisa ngokuqhelekileyo yenziwe ngesilinda esiphindiweyo esisebenza-nye kunye nomnwe wohlobo olunqamlezayo.Emva kokuba igesi ingene kumbindi ophakathi we-cylinder, iya kutyhala iipiston ezimbini ukuba zihambe kumacala omabini, ngaloo ndlela iqhube intonga yokudibanisa ukuze ihambe, kwaye iziphelo zeminwe ezinqamlekileyo ziya kulungisa ngokuqinileyo i-workpiece;ukuba akukho moya ungena kumngxuma ophakathi, ipiston iya kuba phantsi kwesenzo se-spring thrust Setha kwakhona, i-workpiece esisigxina iya kukhutshwa.

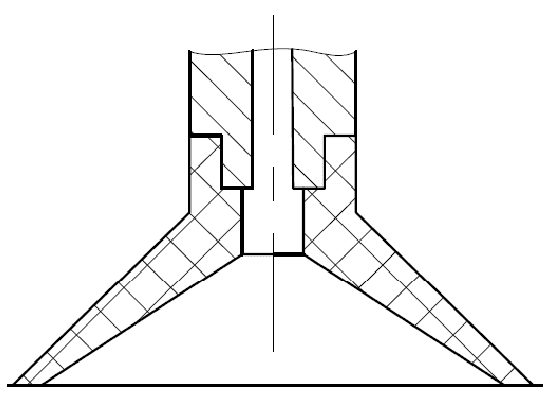

Umzobo 4. Ubume bomnqamlezo woguqulo oluphindiweyo lwendlela yokudibanisa Izixhobo zokusebenza ezinodonga olubhityileyo ezinemingxuma engaphakathi.Emva kokuba i-clamping mechanism ibambe i-workpiece, ukuze kuqinisekiswe ukuba inokubekwa kakuhle kunye nomngxuma ongaphakathi, ngokuqhelekileyo iminwe emithathu ifakwe.

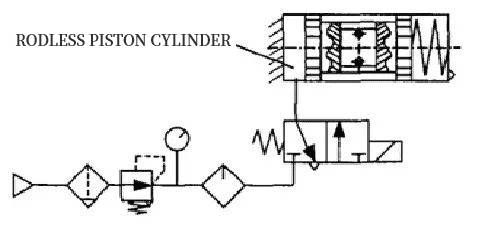

Umzobo 5 Umzobo wesakhiwo sohlobo lwe-lever-type clamping yentonga yenkxaso yangaphakathi 5. I-booster mechanism eqhutywa yi-cylinder ye-piston egxininisiweyo ye-rodless Ngaphantsi kwesenzo samandla asentwasahlobo, ukubuyisela umva kuphunyezwa nge-valve ye-solenoid eneendlela ezimbini.

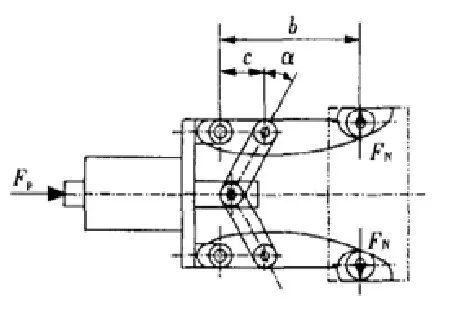

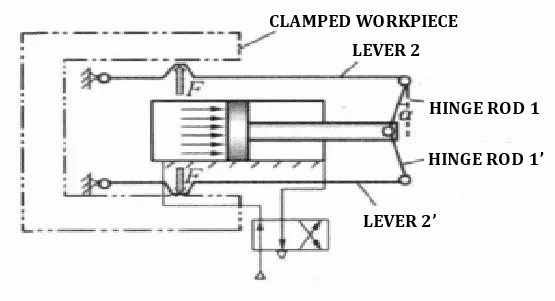

Umzobo we-6 Inkqubo ye-Pneumatic ye-cylinder ye-rodless ye-piston Isilayidi sokutshintsha sifakwe kwi-radial position ye-piston ye-rodless piston cylinder, kunye neentonga ezimbini ze-hinge zixhomekeke ngokulinganayo kuzo zombini iziphelo zesilayidi.Ukuba amandla angaphandle asebenza kwipiston, ipiston iya kushukuma ngasekhohlo nasekunene, ngaloo ndlela ityhala isilayida ukuba siye phezulu nasezantsi.Xa inkqubo ixinzelelwe, i-hinge point B iya kwenza isindululo setyhula malunga nenqaku A, kwaye ukunyuka nokuhla kwentshukumo yesilayidi kunokongeza idigri yenkululeko, kwaye i-oscillation yenqaku C ithatha indawo ye-oscillation ye-cylinder yonke. vimba.

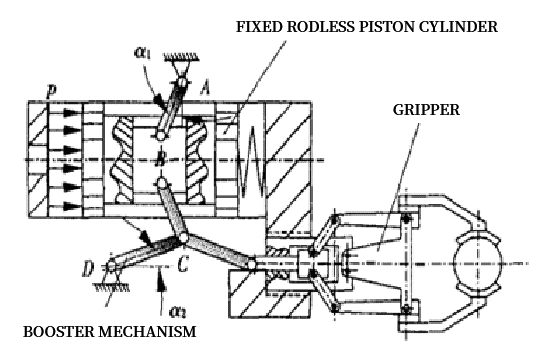

Umzobo 7 Indlela yokuqinisa amandla eqhutywa sisilinda yepiston esisigxina

Xa ivalve yokulawula yomoya ocinezelweyo ikwimeko esekhohlo yokusebenza njengoko kubonisiwe kumzobo, umngxuma osekhohlo wesilinda ye-pneumatic, oko kukuthi, umngxuma ongenantonga, ungena kumoya ocinezelekileyo, kwaye ipiston iya ngasekunene phantsi. isenzo soxinzelelo lomoya, ukwenzela ukuba i-angle yoxinzelelo α ye-hinge rod iyancipha ngokuthe ngcembe.Incinci, uxinzelelo lomoya lukhuliswa yimpembelelo ye-angle, kwaye emva koko amandla adluliselwe kwi-lever ye-lever ye-lever yamandla eqhubekayo, amandla aya kwandiswa kwakhona, kwaye abe yi-force F yokunyanzelisa i-workpiece.Xa ivalve yokulawula i-directional ikwimeko esebenzayo yendawo echanekileyo, umgodi wentonga kumngxunya osekunene we-cylinder ye-pneumatic ungena kumoya oxinzelelweyo, utyhale ipiston ukuba iye ngasekhohlo, kwaye indlela yokubambelela ikhupha i-workpiece.

Umzobo 8. I-internal clamping pneumatic manipulator yehinge rod kunye ne-2 lever series booster mechanism

Iindlela ezimbini zokubamba zokufunxa isiphelo

Indlela yokutsala isiphelo sokufunxa umoya isebenzisa amandla okufunxa akhiwe luxinzelelo olubi kwikomityi yokufunxa ukuhambisa into.Isetyenziselwa ikakhulu ukubamba iglasi, iphepha, intsimbi kunye nezinye izinto ezinobume obukhulu, ubukhulu obuphakathi kunye nobungqongqo obuhlwempuzekileyo.Ngokweendlela zokuvelisa uxinzelelo olubi, lunokwahlulwa lube kwezi ntlobo zilandelayo: 1. Cula ikomityi yokufunxa Umoya okwikomityi yokufunxa ukhutshelwa ngaphandle ngamandla ocinezelayo asezantsi, ukuze uxinzelelo olubi lwenziwe ngaphakathi kwekomityi yokufunxa, kunye nokufunxa. amandla akhiwa ukufunxa into.Isetyenziselwa ukubamba izixhobo zokusebenza ezinemilo encinci, ubukhulu obuncinci kunye nobunzima obulula.

Umfanekiso 9 Umzobo wesakhiwo sekomityi yokufunxa 2. Ukuhamba komoya okungalunganga koxinzelelo lwekomityi yokufunxa ivelufa itshiza umoya ocinezelweyo ophuma kwimpompo yomoya ophuma kumbhobho, kwaye ukuhamba komoya ocinezelweyo kuya kuvelisa ijethi enesantya esiphezulu, esiya kuthatha. kude umoya kwikomityi yokufunxa, ukuze ikomityi yokufunxa ibe kwikomityi yokufunxa.Uxinzelelo olubi lwenziwa ngaphakathi, kwaye ukufunxa okwenziwe luxinzelelo olubi kunokufunxa i-workpiece.

Umfanekiso we-10 Umzobo wesakhiwo sokuhamba komoya ikomityi yokufunxa uxinzelelo

3. Ikomityi yokufunxa yempompo yokufunxa isebenzisa ivalve yolawulo lombane ukudibanisa impompo yokufunxa nekomityi yokufunxa.Xa umoya umpontshwa, umoya ongaphakathi kwikomityi yokufunxa uyakhutshwa, wenze uxinzelelo olubi kunye nokufunxa loo nto.Ngokuchaseneyo, xa ivalve yokulawula idibanisa ikomityi yokufunxa emoyeni, ikomityi yokufunxa ilahlekelwa ukufunxa kwaye ikhuphe i-workpiece.

Umfanekiso we-11 Umzobo wesakhiwo sempompo yokufunxa ikomityi yokufunxa

Iindlela ezintathu zokubamba i-hydraulic end clamping

1. Ngokuqhelekileyo i-clamping ye-clamping ivaliwe: Isixhobo sokugaya sigxininiswe ngamandla anamandla okuqinisa kwangaphambili entwasahlobo kwaye akhululwe nge-hydraulically.Xa i-clamping mechanism ingawenzi umsebenzi wokubamba, ikwimo yokusibamba isixhobo sokomba.Isakhiwo salo esisisiseko kukuba iqela lemithombo egxininiswe ngaphambili lisebenza kwindlela yokunyusa amandla njenge-ramp okanye i-lever, ukwenzela ukuba isihlalo sokutyibilika sihamba nge-axially, siqhube i-slip ukuba sihambe nge-radially, kwaye sibambe isixhobo sokugaya;ioli ephezulu yoxinzelelo ingena kwisihlalo sokutyibilika kwaye I-cylinder ye-hydraulic eyenziwe yi-casing iphinda icinezele i-spring, ibangela ukuba isihlalo se-slip kunye ne-slip sihambe kwelinye icala, ukukhulula isixhobo sokugaya.2. Ngokuqhelekileyo indlela yokudibanisa evulekileyo: Ngokuqhelekileyo ithatha ukukhululwa kwentwasahlobo kunye ne-hydraulic clamping, kwaye ikwimeko yokukhululwa xa umsebenzi wokubamba ungenziwa.Indlela yokubamba ixhomekeke ekugxininisweni kwe-hydraulic cylinder ukuvelisa amandla okubamba, kwaye ukuncitshiswa koxinzelelo lwe-oyile kuya kukhokelela ekunciphiseni amandla okubamba.Ngokuqhelekileyo, i-lock hydraulic lock kunye nokusebenza okuthembekileyo ifakwe kwisekethe yeoli ukugcina uxinzelelo lweoyile.3. Indlela yokuqinisa i-hydraulic tightening clamping: Zombini ukukhulula kunye ne-clamping zibonwa ngoxinzelelo lwe-hydraulic.Ukuba ii-oyile zokungenisa iisilinda zehydraulic kumacala omabini ziqhagamshelwe kwi-oyile yoxinzelelo oluphezulu, iziliphu ziya kuvala embindini kunye nokuhamba kwepiston, zibambe isixhobo sokomba, kwaye zitshintshe I-oyile yoxinzelelo oluphezulu, iziliphu zihamba. kude neziko, kwaye isixhobo sokomba siyakhululwa.

4. I-Compound hydraulic clamping mechanism: Esi sixhobo sine-cylinder ye-hydraulic cylinder kunye ne-axiliary hydraulic cylinder, kunye nesethi yemithombo ye-disc ixhunyiwe kwicala le-cylinder ye-hydraulic cylinder.Xa ioli yoxinzelelo oluphezulu ingena kwi-cylinder ye-hydraulic cylinder, ityhala ibhloko ye-hydraulic cylinder block ukuba ihambe, kwaye idlule kwikholamu ephezulu.Amandla adluliselwa kwisihlalo sokutshiza kwicala le-cylinder ye-hydraulic cylinder, i-disc spring igxininiswe ngakumbi, kwaye isihlalo se-slip sihamba;ngelo xesha, isihlalo sokutyibilika kwicala eliphambili le-hydraulic cylinder sihamba phantsi kwesenzo samandla entwasahlobo, sikhulula isixhobo sokugaya.

Iindlela ezine ezibambekayo zokuphela kwemagnethi

Yahlulwe ngokweekomityi zokufunxa zombane kunye neekomityi zokufunxa ezisisigxina.

I-electromagnetic chuck kukutsala kunye nokukhulula izinto ze-ferromagnetic ngokuvula kunye nokucima umsinga okhoyo kwikhoyili, ukuvelisa kunye nokuphelisa amandla kazibuthe.Ikomityi esisigxina yokufunxa umazibuthe isebenzisa amandla kazibuthe entsimbi esisigxina umazibuthe ukutsala izinto zeferromagnetic.Itshintsha isiphaluka somgca wemagnethi kwikomityi yokufunxa ngokuhambisa into yokwahlula imagnethi, ukuze kuphunyezwe injongo yokutsala kunye nokukhulula izinto.Kodwa ikwayi-sucker, kwaye amandla okufunxa efunxa esisigxina awamkhulu kangako njengaleyo ye-electromagnetic sucker.

Ixesha lokuposa: May-31-2022