Kukho iindlela ezintathu zokulawula i-servo motor: i-pulse, i-analog kunye nonxibelelwano.Sinokuyikhetha njani indlela yokulawula ye-servo motor kwiimeko ezahlukeneyo zesicelo?

1. Imowudi yokulawula i-Pulse ye-servo motor

Kwezinye izixhobo ezincinci zokuma zodwa, ukusetyenziswa kokulawula i-pulse ukuqonda indawo yokumisa imoto kufuneka ibe yeyona ndlela iqhelekileyo yesicelo.Le ndlela yokulawula ilula kwaye kulula ukuyiqonda.

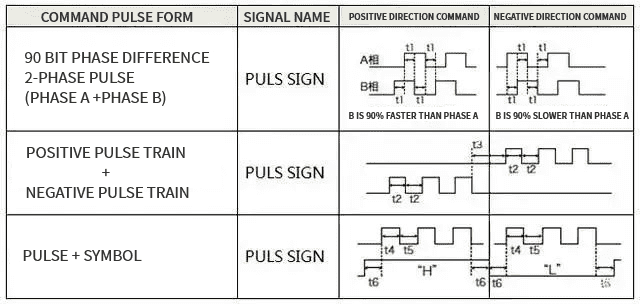

Ingcamango yolawulo olusisiseko: inani elipheleleyo lee-pulses ligqiba ukuhamba kweemoto, kwaye i-pulse frequency inquma isantya semoto.I-pulse ikhethiwe ukuqonda ulawulo lwe-servo motor, vula i-manual ye-servo motor, kwaye ngokubanzi kuya kubakho itafile efana nale ilandelayo:

Zombini zilulawulo lwe-pulse, kodwa ukuphunyezwa kwahlukile:

Eyokuqala kukuba umqhubi ufumana i-pulses ezimbini ze-high-speed (A kunye ne-B), kwaye unqume indlela yokujikeleza kwemoto ngokusebenzisa umahluko wesigaba phakathi kwee-pulses ezimbini.Njengoko kuboniswe kumzobo ongentla, ukuba isigaba B si-90 degrees ngokukhawuleza kunesigaba A, kukujikeleza phambili;emva koko isigaba B sicotha ngama-90 kunesigaba A, kukujikelezisa umva.

Ngexesha lokusebenza, ii-pulses zesigaba ezibini zolu lawulo ziyatshintshana, ngoko ke sibiza le ndlela yokulawula umahluko wolawulo.Ineempawu zokwahlula, nto leyo ebonisa ukuba le ndlela yokulawula, i-pulse yokulawula inamandla aphezulu okuchasana nokuphazamiseka, kwezinye iimeko zesicelo ngokuphazamiseka okunamandla, le ndlela ikhethwayo.Nangona kunjalo, ngale ndlela, enye i-motor shaft kufuneka ithathe izibuko ezimbini ze-high-speed pulse, ezingafanelekanga kwimeko apho i-high-speed pulse port iqinile.

Okwesibini, umqhubi usafumana ii-pulses ezimbini zesantya esiphezulu, kodwa ezimbini ze-high-speed pulses azikho ngexesha elinye.Xa enye i-pulse ikwimo yemveliso, enye kufuneka ibekwimo engasebenziyo.Xa le ndlela yokulawula ikhethiwe, kufuneka kuqinisekiswe ukuba kukho i-pulse output enye kuphela ngexesha elinye.Iipulses ezimbini, isiphumo esinye sibaleka kwicala elilungileyo kwaye elinye libaleka kwicala elingalunganga.Njengoko kule meko ingasentla, le ndlela ikwafuna amazibuko amabini anesantya esiphezulu se-pulse kwishaft enye yeemoto.

Uhlobo lwesithathu kukuba umqondiso omnye we-pulse kufuneka unikwe umqhubi, kwaye ukusebenza kwangaphambili kunye nokubuyisela umva kwemoto kunqunywe ngumqondiso omnye we-IO.Le ndlela yokulawula ilula ukulawula, kunye nokusebenza kobutyebi be-high-speed pulse port nako kuncinci.Kwiinkqubo ezincinci eziqhelekileyo, le ndlela inokukhethwa.

Okwesibini, indlela yokulawula i-analog ye-servo motor

Kwimeko yesicelo ekufuneka isebenzise i-servo motor ukuqonda ukulawulwa kwesantya, sinokukhetha ixabiso le-analog ukuqonda ukulawulwa kwesantya semoto, kwaye ixabiso lexabiso le-analog limisela isantya sokuhamba kwemoto.

Kukho iindlela ezimbini zokukhetha ubuninzi be-analog, yangoku okanye i-voltage.

Imowudi yombane: Udinga kuphela ukongeza i-voltage ethile kwi-terminal yesiginali yokulawula.Kwezinye iimeko, ungasebenzisa i-potentiometer ukufezekisa ulawulo, olulula kakhulu.Nangona kunjalo, i-voltage ikhethwe njengesignali yokulawula.Kwimeko enzima, i-voltage iphazamiseka ngokulula, ibangele ulawulo olungazinzanga.

Imowudi yangoku: Imodyuli ehambelanayo yangoku iyafuneka, kodwa isignali yangoku inamandla okumelana nokuphazamiseka kwaye ingasetyenziselwa kwiimeko ezinzima.

3. Indlela yokulawula unxibelelwano lwe-servo motor

Iindlela eziqhelekileyo zokuqonda ulawulo lwe-servo motor ngonxibelelwano yi-CAN, i-EtherCAT, i-Modbus, kunye ne-Profibus.Ukusebenzisa indlela yonxibelelwano ukulawula imotor yindlela yokulawula ekhethwayo kwezinye iimeko ezinzima kunye nezinkulu zesicelo senkqubo.Ngale ndlela, ubungakanani benkqubo kunye nenani lee-motor shafts zinokulungelelaniswa ngokulula ngaphandle kocingo olunzima lokulawula.Inkqubo eyakhiweyo ibhetyebhetye kakhulu.

Okwesine, inxalenye yokwandisa

1. Ulawulo lwe-torque ye-Servo

Indlela yokulawula i-torque kukuseta i-torque ye-output yangaphandle ye-motor shaft ngokusebenzisa igalelo lobuninzi be-analog yangaphandle okanye ukunikezelwa kwedilesi ngqo.Ukusebenza okuthe ngqo kukuba, umzekelo, ukuba i-10V ihambelana ne-5Nm, xa ubuninzi be-analog yangaphandle ibekwe kwi-5V, i-motor shaft yi-Outout yi-2.5Nm.Ukuba umthwalo we-motor shaft ungaphantsi kwe-2.5Nm, i-motor ikwimeko yokukhawuleza;xa umthwalo wangaphandle ulingana ne-2.5Nm, i-motor ikwisantya esiqhubekayo okanye i-stop state;xa umthwalo wangaphandle uphezulu kune-2.5Nm, i-motor ikwimeko yokunciphisa okanye i-reverse acceleration state.I-torque esetyenzisiweyo ingatshintshwa ngokutshintsha ukusekwa kobuninzi be-analog ngexesha langempela, okanye ixabiso ledilesi ehambelanayo inokutshintshwa ngonxibelelwano.

Isetyenziswa ikakhulu kwizixhobo zokujija kunye nokukhulula ezineemfuno ezingqongqo kunyanzeliso lwento, njengezixhobo zokujija okanye izixhobo zokutsalwa kwefiber optical.Ukumiswa kwe-torque kufuneka kutshintshwe nanini na ngokuhambelana nokutshintshwa kwe-radius ejikelezayo ukuze kuqinisekiswe ukuba ukunyanzeliswa kwezinto eziphathekayo akuyi kutshintsha kunye nokutshintshwa kwe-radius ejikelezayo.utshintsho kunye neradiyasi ejikelezayo.

2. Ulawulo lwendawo ye-Servo motor

Kwimo yokulawula isikhundla, isantya sokujikeleza ngokuqhelekileyo sichongwa ngokuphindaphindiweyo kwee-pulses zokufakelwa kwangaphandle, kwaye i-angle yokujikeleza inqunywe ngamanani e-pulses.Ezinye ii-servos zinokunika ngokuthe ngqo isantya kunye nokufuduka ngonxibelelwano.Ekubeni imo yesikhundla inokuba nolawulo olungqongqo kakhulu kwisantya kunye nendawo, isetyenziswa ngokubanzi kwizixhobo zokubeka, izixhobo zoomatshini be-CNC, oomatshini bokushicilela njalo njalo.

3. Imowudi yesantya se-Servo motor

Isantya sokujikeleza sinokulawulwa ngegalelo lobuninzi be-analog okanye i-pulse frequency.Imowudi yesantya ingasetyenziselwa ukubeka indawo xa i-loop yangaphandle yolawulo lwe-PID yesixhobo solawulo oluphezulu lunikezelwa, kodwa isignali yendawo yemoto okanye isignali yendawo yomthwalo othe ngqo kufuneka ithunyelwe kwikhompyutheni ephezulu.Ingxelo ngokusetyenziswa kokusebenza.Imowudi yokuma ikwaxhasa umthwalo othe ngqo welophu yangaphandle ukuze ibone isignali yendawo.Ngeli xesha, i-encoder kwi-motor shaft end ibona kuphela isantya semoto, kwaye isignali yendawo inikezelwa ngesixhobo sokugqibela esithe ngqo sokugqiba umthwalo.Inzuzo yoku kukuba inokunciphisa inkqubo yosulelo oluphakathi.Impazamo yandisa ukuchaneka kokumiswa kwenkqubo yonke.

4. Thetha ngeeringi ezintathu

I-servo ilawulwa ngokubanzi ngamalophu amathathu.Izinto ezibizwa ngokuba zii-loops ezintathu ziinkqubo zohlengahlengiso lwe-PID ezivaliweyo ezivaliweyo.

I-loop ye-PID yangaphakathi yi-loop yangoku, eyenziwa ngokupheleleyo ngaphakathi komqhubi we-servo.Imveliso yangoku yesigaba ngasinye semoto kwi-motor ifunyenwe kwisixhobo seHolo, kwaye impendulo engalunganga isetyenziselwa ukulungelelanisa ulungelelwaniso lwangoku lokulungiswa kwe-PID, ukuze kuphunyezwe imveliso yangoku ngokusondeleyo kangangoko kunokwenzeka.Ngokulingana neseti yangoku, i-loop yangoku ilawula i-motor torque, ngoko kwimodi ye-torque, umqhubi unomsebenzi omncinci kunye nempendulo eguquguqukayo ngokukhawuleza.

I-loop yesibini yi-loop yesantya.Uhlengahlengiso olubi lwengxelo ye-PID lwenziwa ngophawu olufunyenweyo lwe-encoder yemoto.Imveliso ye-PID kwi-loop yayo ngokuthe ngqo ukusetwa kwe-loop yangoku, ngoko ulawulo lwe-loop yesantya lubandakanya i-speed loop kunye ne-loop yangoku.Ngamanye amagama, nayiphi na indlela kufuneka isebenzise i-loop yangoku.I-loop yangoku isiseko solawulo.Ngelixa isantya kunye nesikhundla silawulwa, inkqubo ngokwenene ilawula okwangoku (i-torque) ukufezekisa ulawulo oluhambelanayo lwesantya kunye nesikhundla.

Iluphu yesithathu yi-loop yendawo, eyilophu engaphandle.Inokwakhiwa phakathi komqhubi kunye ne-encoder motor okanye phakathi komlawuli wangaphandle kunye ne-encoder motor okanye umthwalo wokugqibela, kuxhomekeke kwimeko yangempela.Ekubeni isiphumo sangaphakathi se-loop yokulawula indawo kukuseta isantya sesantya, kwimowudi yokulawula indawo, inkqubo yenza imisebenzi yazo zontathu iilophu.Ngeli xesha, inkqubo inelona nani likhulu lokubala kunye nesantya esicothayo esiguqukayo.

Phezulu zivela kwiNdaba zaseChengzhou

Ixesha lokuposa: May-31-2022